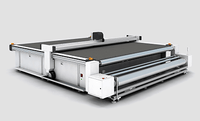

Introducing the JWEI TB08II Series Digital Cutting Tables – Precision, Efficiency, and Consistency Redefined!

Elevate your advertising production with the cutting-edge JWEI TB08II Series Digital Cutting Tables – your key to unparalleled efficiency and a new standard of consistency in the industry.

Why choose the TB08II series? It's not just a cutting table; it's a strategic partner in optimizing your production workflow. Trim your processes with surgical precision and set a benchmark for finished products in the advertising industry.

Versatility Unleashed: The TB08II series is the go-to choice for customers dealing with a diverse range of printed advertising materials. From corrugated paperboard to cardboard, grey board to KT board, PVC expansion sheet to honeycomb board – it conquers them all. It's your trusted ally for materials like car stickers, light slices, PP gum, flex banners, flag fabric, EPE foams, EVA, PVC plates, acrylic, thick foam, and more.

Solid Foundation: Framed by butt-end-joint industrial aluminum alloy profiles, the TB08II series delivers unparalleled rigidity and stability. It's not just efficient; it's easy to transport and assemble, making it the ideal solution, especially in spaces with limited entrances.

Adaptable Tools: The modularized cutting head supports up to 3 sets of tool combinations, giving you the flexibility to tailor your cutting process to your specific needs.

Powerful Routing: Opt for the optional high-power router assembly with a vacuum cleaner system (1800w, max. 60,000RPM) for precise routing and cleaning, meeting the demands of even the most intricate projects.

Automatic Tool Changer (ATC): Take your production capabilities to the next level with the optional ATC for routing, trimming, and polishing rigid plates like acrylic, PVC foam board, MDF, ABS, and various plastic boards.

Industrial-Grade Reliability: The carbon fiber-reinforced gantry ensures intense industrial production, providing reliability and stability that you can count on.

Maximum Holding-Down Force: Separate vacuum areas are strategically designed to maximize holding-down force, ensuring your materials stay in place during the cutting process.

Intuitive Control: The JWCS control software, included as standard, features a friendly interface with powerful editing and optimizing functions, putting you in complete control of your production process.

Ready to revolutionize your cutting experience? Choose the JWEI TB08II Series Digital Cutting Tables – where precision meets performance! Contact us now to explore the future of efficient and consistent advertising production

Specifications

| Model No. | CB08II-2516PM 3516PM 5516PM 2520PM 3520PM 5520PM 3032PM |

| Multifunctional head | Oscillating knife, offset knife, rotary knife,snip knife, cursor, drawing, automatic feeding |

| Safety device | Infrared sensor, responsive, safe and reliable |

| moving speed | Up to 1500 mm/s |

| Cutting speed | Up to 1200 mm/s(Depends on different materials) |

| Cutting thickness | Up to 50mm(Depends on different materials) |

| Cutting material | UV material, outdoor printing fabric, light sheet, gridding cloth, flag fabric, stickers, KT board, PVC expansion sheet, corrugated paper, honey comb board etc. |

| Servo precisiony | +/-0.01mm |

| Repeat precision | +/-0.05mm |

| Buffer memory | 2GB |

| Interface | Ethernet port |

| Material fixing meathod | Vacuum adsorption |

| Work command | HP-GL compliant format |

| Transmission system | Servo driver, high precise gear |

| Numerical control panel | EN LED Touch screen |

| Power Supply | AC 380V+/-10% |

| Working Environment | Temperature 0-35 degree; Humidity 60% - 80% |

| Effective Cutting Area | 2500mm*1600mm|3500*1600|5500*1600|2500*2000|3500*2000|5500*2000|3000*3200 |

| Machine Size(mm) | 3370mm*2380mm*1300mm(not including automatic board loading system) |

Video

Brochure